- Home

- Raw & Refractory Materials

- Raw materials for refractory products

Raw materials for refractory products

Raw materials for refractory products such as sintered magnesia (DBM in various grades), fused alumina, fused magnesia, alumina, bauxite, and natural flake graphite.

a.1- Low Grade DEAD BURNED MAGNESITE (DBM)

Dead Burnt Magnesite is produced in the Rotary Kiln by sintering raw magnesite at a controlled temperature of 1750 degree centigrade and its

chemically inactive. Dead Burnt Magnesite is consuming almost exclusively in the production of Refractory Field.

It is used in brick making and raw materials for producing unshaped refractories. The finished products are used for steelmaking, bottom of electric furnace and ramming lining.

|

MAIN PHYSICLAND CHEMICAL INDEXES |

|||||||

|

INDEXES OR AND |

Chemical Composition (%) |

L.O.L max |

B.D (g/cm3) min |

Grain Size |

|||

|

MgO min |

Sio2 max |

CaO max |

Fe2O3 + Al2O3 max |

||||

|

ms-92 |

92.00 |

4.00 |

1.60 |

2.50 |

0.30 |

3.18 |

From 80 mesh |

|

ms-91 |

91.00 |

4.50 |

1.80 |

2.60 |

0.30 |

3.18 |

To 325 mesh |

|

Ms-90 |

90.00 |

4.80 |

2.50 |

3.00 |

0.30 |

3.15 |

0-3 mm 0-10 mm 3-15 mm 3-30 mm 5-60 mm 0-120 mm |

a.2- Middle Grade Dead Burnt Magnesite

Middle Grade Dead Burned Magnesite is made from Caustic Calcined magnesite with MgO above 95% through processes of briquetting, sintering in shaft kilns at high temperature. Featured by good sintering level and dense structure.

It is an amorphous refractory material for producing magnesia branded bricks, medium-grade magnesia bricks, magnesia castables, etc. It is also a high-quality raw material for magnesia refractory products.

|

indexes |

MGO % min |

SIO2 % max |

CAO % max |

LOI % max |

B.D.gm/cm3 min |

|

DBM-95 |

95 |

3.00 |

2.00 |

0.50 |

3.18 |

|

DBM-94 |

94 |

3.50 |

2.50 |

0.50 |

3.16 |

a.3- High Purity Dead Burnt Magnesite

High Purity Dead Burned Magnesite is made from finely selected super grade -A raw magnesite through processes of floatation concentration, calcinations, milling, briquetting, and sintering in ultra-high temperature oil shaft kilns. It is an ideal raw material for high-grade magnesia refractories such as magnesia bricks, magnesia soldering bricks, magnesia-carbon bricks, tamping materials for tundishes and magnesia castables.

|

MGO % min |

SIO2 % max |

CAO % max |

LOI % max |

B.D.gm/cm3 min |

|

|

DBM-97 |

97 |

1.50 |

1.50 |

0.50 |

3.20 |

|

DBM96 |

96 |

1.80 |

2.0 |

0.50 |

3.20 |

Fused Magnesia

Fused magnesia (FM) is produced by smelting of calcined magnesia in electric arc furnaces at above 3000°C. Fused magnesia is considered to be one of the best thermal and electrical insulators with high density, high purity and large crystals. Kuma’s produces fused magnesia with capacity of 37.500 tons per year.

FM can be used in:

– High performance MgO-C refractory bricks for steel industry

– Fired refractory bricks for cement and glass industry

Fused Magnesia Grades

|

Chemical Analysis ( Weight %) |

Bulk Density (gr/cm3)* |

Crystal Size (µm) |

Grain Size (mm) |

||||||

|

MgO |

SiO2 |

CaO |

Fe2O3 |

Al2O3 |

LOI |

||||

|

FM97,5 |

97,50 |

0,65 |

1,35 |

0,40 |

0,10 |

0,06 |

3,48 |

800 |

5-40 |

|

FM97 |

97,00 |

0,75 |

1,65 |

0,50 |

0,10 |

0,06 |

3,47 |

700 |

5-40 |

|

FM96,5 |

96,50 |

1,00 |

2,00 |

0,50 |

0,10 |

0,06 |

3,46 |

600 |

5-40 |

|

FM96 |

96,00 |

1,10 |

2,20 |

0,60 |

0,10 |

0,06 |

3,45 |

600 |

5-40 |

|

FM95 C |

94,70 |

2,00 |

2,50 |

0,70 |

0,10 |

0,06 |

3,30 |

300 |

5-40 |

1-Calcined Alumina Powder

AW series of α-AL2O3 powder is the national project achievement and has passed the national technical appraisal, quality can be instead of Amati’s. It uses a unique process and possesses the characteristics of high activity, small grains and high conversion rate.

It is the main raw material for the high quality refractory products, as well as fine ceramics and polishing products. It is on the basis of establishing the control model of fine particle size, effectively controls and optimizes the particle size distribution. Meanwhile it makes phase change and surface modification to own small crystal grain size and crystal-like, spherical-like properties.

|

Model |

AW-4M |

AW-12M |

AW-06L |

||||

|

Composition% |

Guarantee value |

Typical value |

Guarantee value |

Typical value |

Guarantee value |

Typical value |

|

|

AL2O3 |

≥99.00 |

99.37 |

≥99 |

99.60 |

≥99 |

99.60 |

|

|

SiO2 |

≤0.20 |

0.10 |

≤0.20 |

0.12 |

≤0.20 |

0.11 |

|

|

Fe2O3 |

≤0.20 |

0.06 |

≤0.20 |

0.08 |

≤0.20 |

0.08 |

|

|

Na2O |

≤0.30 |

0.25 |

≤0.20 |

0.06 |

≤0.20 |

0.06 |

|

|

α-AL2O3Conversion rate % |

≥91 |

93 |

≥95 |

≥95 |

|||

|

Particle size D50µn |

3~5 |

4.47 |

1.0~1.5 |

1.23 |

0.6-1.0 |

0.80 |

|

|

Particle distribution |

Unimodal |

Unimodal |

Unimodal |

||||

|

Test standard |

GB/T3044-89 ; |

GB3604-83 |

|||||

|

Package |

25KglBag, 1 Ton/Bag; or As customers’ requirement |

||||||

2-Tabular Alumina

Tabular alumina is a purely sintered α-corundum material that is a compact body rapidly sintered at temperatures above 1900 ° C without sintering aids. Tabular alumina has approximately 200 μm and well-developed hexagonal plate-like α-corundum crystals. Its excellent thermal volume stability and thermal shock resistance can be attributed to the following special microstructure of platy corundum: less open pores, large crystals, closed spherical pores due to recrystallization trap during rapid sintering. Tabular alumina has high heat resistance, mechanical strength, abrasion resistance, high chemical purity, excellent insulation properties, acid and alkali corrosion resistance.

|

Chemical composition |

Physical property |

Note |

|||||||

|

AL2O3 |

Na2O |

Sio2 |

Fe203 |

Bulk density |

Apparent porosity |

Water absorption |

|||

|

≥ |

≤ |

≤ |

≤ |

≥g/cm3 |

% |

% |

|||

|

Particle size |

DT-60 |

99.3 |

0.40 |

0.13 |

0.05 |

3.55 |

3.0 |

1.0 |

(µm): 5-10, 3-5, 3-1, 1-0, 0.5-1, 0.2-0.6 |

|

Powder |

DT-60 |

99.1 |

0.40 |

0.15 |

0.07 |

3.50 |

5.0 |

1.5 |

(µm). -45 µm (-325mesh) -30 µm (-500mesh) |

|

Package |

25KglBag, 1 Ton/Bag; or As customers’ requirement |

||||||||

3-White Fused Alumina

White fused alumina / White Corundum is a high grade refractory material, which is mainly made from industrial alumina powder by melting above 2000 ℃ in the electric arc furnace and cooling, classified into different parcel size. It has close texture and high hardness. Its particle is in sharp corners. It is suitable for kinds of advanced finalized refractories and amorphous refractories. It also can be used for high temperature, abrasion resistance and erosion resistance environment, such as steel ladle, sliding plate, nozzle, stopper rod, ventilated brick, iron ditch, kiln and coal spraying pipe.

|

Item |

White fused alumina % |

|

|

Chemical |

Al2O3 |

≥99.0 |

|

Composition % |

Na2O |

≤0.4 |

|

Fe2O3 |

≤0.1 |

|

|

SiO2 |

≤0.15 |

|

|

TiO2 |

≤0.5 |

|

|

Color |

White |

|

|

True Density |

>3.90g/cm3 |

|

|

Packing |

25kg/bag or 1 ton/bag |

|

|

Particle size |

0-1-3-5-8mm, 180/200/325 mesh |

|

4-Brown Fused Alumina

Our brown corundum is made of quality bauxite as raw material, anthracite and iron filings. It is made by arc smelting at 2000°C or higher temperature. It is crushed and plasticized by self-grinding machine, magnetically selected to remove iron, sieved into various sizes, and its texture is dense and hard. High, spherical pellets, suitable for the production of ceramic, high-resistance abrasive resin and grinding, polishing, sandblasting, precision casting, etc., can also be used to manufacture high-grade refractories.

|

Brown Fused Alumina |

||||||

|

Items |

Al2O3 |

Fe2O3 |

SiO2 |

Bulk |

Color |

Application |

|

density |

||||||

|

Grade I |

≥95 |

≤0.3 |

≤1.5 |

3.85 |

Maroon |

Refractory material, |

|

fine polishing |

||||||

|

Grade II |

≥95 |

≤0.3 |

≤1.5 |

3.85 |

Black particle; |

Polishing, grinding |

|

Gray powder |

||||||

|

Grade III |

≥95 |

≤0.3 |

≤1.5 |

3.85 |

Black particle; |

Grinding, cutting, |

|

Gray powder |

sandblasting |

|||||

|

Grade IV |

≥95 |

≤0.3 |

≤1.5 |

3.85 |

Black particle; |

Polishing, grinding |

|

Gray powder |

||||||

|

Grade V |

≥95 |

≤0.3 |

≤1.5 |

3.85 |

Black particle; |

Floor |

|

Gray powder |

|

|||||

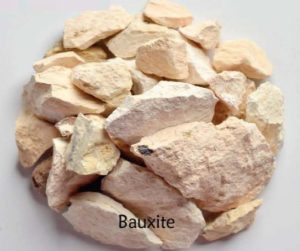

The composition of Bauxite is very complex, and the general term of Hydrous Alumina Ore with different geological origin. Such as boehmite, diaspore and gibbsite (Al2O3 – 3H2O); some are diaspore and kaolinite (2SiO2 Al2O3 2H2O); some kaolinite, and with the increase of the content of kaolinite, which is generally the bauxite or kaolinite clay. Bauxite is usually formed by chemical weathering or exogamic action. There are few pure minerals and always contain some foreign minerals, which contain more or less clay minerals, iron minerals, titanium minerals and detrital heavy minerals.

|

Brand Number |

Technical specifications |

||||

|

Fixed Carbon(≥%) |

Volatile(≤%) |

Ash(≤%) |

Moisture(≤%) |

On Sieve(%) |

|

|

LG50-94 LG80-94 LG100-94 LC120-94 LC150-94 |

94.00 |

1.20 |

4.80 |

0.50 |

≥80.00 |

|

LG (-)1OO-94 LG (-)200-94 LG(-)325-94 LG(-)500-94 |

≤20.00 |

||||

|

LG50-95 LG80-95 LG1OO-95 LGl2O-95 LGI50-95 |

95.00 |

1.20 |

3.80 |

0.5 |

≥80.00 |

|

LG (-)100-95 LG (-)200-95 LG(-)325-95 LG(- )500-95 |

≤20.00 |

||||

|

LG50-96 LG8O-96 LGl00-96 LGI20-96 LGI50-96 |

96.00 |

1.20 |

2.80 |

0.5 |

≥80.00 |

|

LG (-) l00-96 LG (-)200-96 LG(-)325-96 LG(-)5OO-96 |

≤20.00 |

||||

|

LG50-97 LG80-97 LG100-97 LG120-91 LG150-97 |

97.00 |

1.0-1.20 |

1.8-2.0 |

0.5 |

≥80.00 |

|

LG (-) I 00 97 LG (-)200-97 LG(-)325-97 LG(-)500-97 |

≤20.00 |

||||

|

LG50-98 LG80-98 LG 100-98 LG 120-98 LG150-98 |

98.00 |

0.70-1.00 |

1.00-1.30 |

0.5 |

≥80.00 |

|

LG (-)100-98 LG (-)200-98 LG(-)325-98 LG(-)500-98 |

≤20.00 |

||||

|

LG50-99 LG80-99 LG100-99LGI20-99 LGI50-99 |

99.00 |

0.35 |

0.65 |

0.5 |

≥80.00 |

|

LG (-) l00-99 LG (-)200-99 LG(-)325-99 LG(-)500-99 |

≤20.00 |

||||

|

Brand Number |

Technical specifications |

||||

|

Fixed Carbon(≥%) |

Volatile(≤%) |

Ash(≤%) |

Moisture(≤%) |

On Sieve(%) |

|

|

LZ50-80 LZ80-80 LZ100-80 LZ120-80 LZ150-80 |

80.00 |

2.70-3.00 |

17.00-17.30 |

1.00 |

≥80.00 |

|

LZ (-)100-80 LZ (-)200-80 LZ (-)325-80 |

≤20.00 |

||||

|

LZ50-83 LZ80-83 LZ100-83 LZ120-80 LZ150-83 |

83.00 |

2.60-3.00 |

14.00-14.40 |

1.00 |

≥80.00 |

|

LZ (-)100-83 LZ (-)200-83 LZ (-)325-83 LZ (-)500-83 |

≤20.00 |

||||

|

LZ50-85 LZ80-85 LZ100-85 LZ120-85 LZ150-85 |

85.00 |

2.30-2.50 |

12.50-12.70 |

1.00 |

≥80.00 |

|

LZ (-)100-85 LZ (-)200-85 LZ (-)325-85 LZ (-)500-85 |

≤20.00 |

||||

|

LZ50-86 LZ80-86 LZ100-86 LZ120-86 LZ150-86 |

86.00 |

2.30-2.50 |

11.50-11.70 |

1.00 |

≥80.00 |

|

LZ (-)100-86 LZ (-)200-86 LZ (-)325-86 LZ (-)500-86 |

≤20.00 |

||||

|

LZ50-87 LZ80-87 LZ100-87 LZ120-87 LZ150-87 |

87.00 |

2.20-2.50 |

10.50-10.80 |

1.00 |

≥80.00 |

|

LZ (-)100-87 LZ (-)200-87 LZ (-)325-87 LZ (-)500-87 |

≤20.00 |

||||

|

LZ50-88 LZ80-88 LZ100-88 LZ120-88 LZ150-88 |

88.00 |

1.80-2.00 |

10-00-10.20 |

1.00 |

≥80.00 |

|

LZ (-)100-88 LZ (-)200-88 LZ (-)325-88 LZ (-)500-88 |

≤20.00 |

||||

|

LZ50-89 LZ80-89 LZ100-89 LZ120-88 LZ150-89 |

89.00 |

1.80-2.00 |

9.00-9.20 |

1.00 |

≥80.00 |

|

LZ (-)100-89 LZ (-)200-89 LZ (-)325-89 LZ (-)500-89 |

≤20.00 |

||||

|

LZ50-90 LZ80-90 LZ100-90 LZ120-90 LZ150-90 |

90.00 |

1.80-2.00 |

8.00-8.20 |

1.00 |

≥80.00 |

|

LZ (-)100-90 LZ (-)200-90 LZ (-)325-90 LZ (-)500-90 |

≤20.00 |

||||

|

LZ50-91 LZ80-91 LZ100-90 LZ120-91 LZ150-91 |

91.00 |

1.40-1.60 |

7.40-7.60 |

1.00 |

≥80.00 |

|

LZ (-)100-91 LZ (-)200-91 LZ (-)325-91 LZ (-)500-91 |

≤20.00 |

||||

|

LZ50-92 LZ80-92 LZ100-92 LZ120-92 LZ150-92 |

92.00 |

1.35-1.55 |

6.45-6.65 |

1.00 |

≥80.00 |

|

LZ (-)100-92 LZ (-)200-922 LZ (-)325-92 LZ (-)500-92 |

≤20.00 |

||||

|

LZ50-93 LZ80-93 LZ100-93 LZ120-93 LZ150-93 |

93.00 |

1.30-1.50 |

5.50-5.70 |

1.00 |

≥80.00 |

|

LZ (-)100-93 LZ (-)200-93 LZ (-)325-93 LZ (-)500-93 |

≤20.00 |

||||